by Keith Baker, KB1SF/VA3KSF and Dick Jansson, KD1K

AMSAT is a worldwide group of Amateur Radio Operators (Hams) who share an active interest in building, launching and then communicating with each other through non-commercial Amateur Radio satellites. By any measure, AMSAT’s track record has been impressive. Since its founding…now over 40 years ago… AMSAT has used predominantly volunteer labor and donated resources to design, construct, and, with the added assistance of international government and commercial agencies, successfully launch, over 60 Amateur Radio satellites into Earth orbit. Today, over 20 of these satellites are operational.

The Radio Amateur Satellite Corporation (as AMSAT is officially known) was formed in 1969 as a not-for-profit, 501(c)(3) educational organization chartered in the District of Columbia. Its aim is to foster Amateur Radio’s participation in space research and communication. Since that time, other like-minded groups throughout the world have formed to pursue the same goals. Many of these groups share the “AMSAT” name. While the affiliations between the various groups are not formal, they do cooperate very closely with one another. For example, international teams of AMSAT volunteers are often formed to help build each other’s space hardware, or to help launch and control each other’s satellites.

The Radio Amateur Satellite Corporation (as AMSAT is officially known) was formed in 1969 as a not-for-profit, 501(c)(3) educational organization chartered in the District of Columbia. Its aim is to foster Amateur Radio’s participation in space research and communication. Since that time, other like-minded groups throughout the world have formed to pursue the same goals. Many of these groups share the “AMSAT” name. While the affiliations between the various groups are not formal, they do cooperate very closely with one another. For example, international teams of AMSAT volunteers are often formed to help build each other’s space hardware, or to help launch and control each other’s satellites.

Since the very first OSCAR satellites (OSCAR stands for Orbiting Satellite Carrying Amateur Radio) were launched in the early 1960s, AMSAT’s international volunteers, often working quite literally in their basements and garages, have pioneered a wide variety of new communications technologies that are now taken for granted in the world’s satellite marketplace. These breakthroughs have included some of the very first satellite voice transponders as well as highly advanced digital “store-and-forward” messaging transponder techniques. All of these accomplishments have been achieved through close cooperation with international space agencies that often have provided launch opportunities at significantly reduced costs in return for AMSAT’s technical assistance in developing new ways to launch paying customers. Spacecraft design, development and construction has also occurred in a fiscal environment of individual AMSAT member donations, thousands of hours of volunteer effort, and the creative use of leftover materials donated from aerospace industries worldwide.

This document will focus on some of the creative technical and managerial techniques that AMSAT has used to work with donated resources and international teams of volunteer talent to design, build and launch commercial grade communications satellites in a not-for-profit environment. Indeed, over the years, some of these techniques have found their way into “for profit” and government space activities.

Beginnings

The story of Amateur Radio satellites begins very near the beginning of America’s other satellite programs. Barely four months after the successful launch of Russia’s Sputnik I, the United States launched Explorer I on 31 January 1958. At about that same time, a West Coast group of Hams began toying with the idea of launching an Amateur Radio satellite into orbit. Far from being simply a “pipe” dream, this group later organized a group called Project OSCAR, with the expressed aim of building and launching amateur satellites.

After a series of high level exchanges among Project OSCAR members, the American Radio Relay League (the largest Amateur Radio fraternal organization in North America), and the United States Air Force, a launch opportunity on Discoverer XXXVI from Vandenberg AFB, California was secured for the very first Amateur Radio satellite called OSCAR I. It was successfully launched into a low Earth orbit on the morning of December 12, 1961…barely four years after the launch of Sputnik I.

OSCAR I weighed in at 10 pounds. It was built, quite literally, in the basements and garages of the Project OSCAR team. It carried a small beacon transmitter that allowed ground stations to measure radio propagation through the ionosphere, as well as the internal temperature of the satellite.

It also was the very first satellite to be ejected as a secondary payload from a primary launch vehicle and then enter a separate orbit. This was accomplished using a very high technology and thermally balanced ejection system…a $1.15 spring from Sears Roebuck!

OSCAR I was an overwhelming success. More than 570 amateurs in 28 countries forwarded observations to the Project OSCAR data reduction center. Unfortunately, OSCAR I lasted only 22 days in orbit before burning up as it re-entered the atmosphere. But Amateur Radio’s “low tech” entry into the “high tech” world of space had been firmly secured. When scientific and other groups asked the Air Force for advice on secondary payloads, the Air Force suggested they study the OSCAR design. What’s more, OSCAR I’s “bargain basement” procurement approach and management philosophy would become the hallmark of all the OSCAR satellite projects that were to follow, even to this day.

OSCAR II was built by the same team, and although it was similar, both structurally and electrically, to OSCAR I, there were a number of improvements to OSCAR II. One such upgrade modified the internal temperature sensing mechanism for improved accuracy. Another improvement modified the external coating of the satellite to achieve a cooler internal environment. Yet another modification lowered the beacon transmitter output to extend the battery life of the satellite. Thus, the “continuous improvement” strategy that has also become a central part of the amateur satellite approach was set into place very early in the program.

OSCAR III quickly followed OSCAR II. OSCAR III would later become the first Amateur Radio satellite to carry a transponder. It was designed to receive a 50 KHz wide band of uplink signals near 146 MHz and then retransmit them (with a power of 1 watt!) near 144 MHz. This would allow amateurs with relatively modest Earth stations to communicate over much longer distances at these frequencies. In fact, it could be argued that the lure of talking over larger and larger distances at these frequencies remains the single most important reason members of the Radio Amateur community have continued to support the construction, launch and use of these satellites over the years. Put another way, the lure of a “repeater in space” that virtually anyone with an entry level Amateur Radio license can use is a very powerful motivator for a group of people who like to communicate with each other as a hobby!

However, the thought of a “repeater in space” developed and launched by a group of “know-nothing Hams” working in their basements and garages wasn’t always looked upon with favor. While details of the incident are sketchy, it’s reported that the builders of TELSTAR I, the first commercial telecommunications satellite, were quite upset to learn that a “rag-tag” group of Hams were also working on a telecommunications satellite called OSCAR III as TELSTAR was nearing completion. For a while, it appeared that OSCAR III might possibly upstage their multi-million dollar TELSTAR effort by beating them to orbit! In fact, it’s also reported that TELSTAR’s builders did eventually change their public relations approach to include the word “commercial” in subsequent references to TELSTAR I as the “world’s first telecommunications satellite”.

OSCAR III’s transponder operated for 18 days and about 1000 amateurs in 22 countries were heard operating through it. The satellite was the first to clearly demonstrate multiple stations could successfully use a satellite simultaneously, a technology that is largely taken for granted in satellite telecommunications today.

The fourth Amateur Radio satellite, OSCAR IV, was targeted for a geostationary circular orbit 21,000 miles above the Earth. OSCAR IV would ride to space aboard a Titan III-C rocket. Unfortunately, despite a valiant effort on the part of the Hams and others involved, (most of whom were members of the TRW Radio Club of Redondo Beach, California), the top stage of the launch vehicle failed, and OSCAR IV never reached its intended orbit. However, despite this apparently “fatal” blow, OSCAR IV operated long enough for amateurs to successfully develop innovative workaround procedures to salvage as much use out of the satellite as possible.

The Birth Of AMSAT

The story of AMSAT actually begins in Australia. There, a group of students at the University of Melbourne had pieced together an amateur satellite that would evaluate the suitability of the 10-meter Amateur Radio band as a downlink frequency for future satellite transponders. It would also test a passive magnetic attitude stabilization scheme (another AMSAT first), and demonstrate the feasibility of controlling a spacecraft via uplink commands. Unfortunately, the completed satellite languished as launch delay followed launch delay.

At about that same time, a group of Radio Amateurs with space-related experience in the Washington DC area met to form what initially became known as the East Coast version of the West Coast Project OSCAR Association.

As a result of this meeting, AMSAT, The Radio Amateur Satellite Corporation, was born. AMSAT was later chartered as a 501(c)(3) educational corporation in the District of Columbia on March 3, 1969. Its aim was (and is) to embrace and expand on the work started by Project OSCAR. The new AMSAT organization selected, as its first task, to arrange for the launch of OSCAR 5.

After some modifications by AMSAT members (again working mostly in their basements and garages) OSCAR 5 (later to be called Australis-OSCAR 5, or simply AO-5) was successfully launched on a National Aeronautics and Space Administration (NASA) vehicle. Previous OSCARs had all been launched using US Air Force rockets. The OSCAR 5 satellite performed nearly flawlessly.

AMSAT-OSCAR Satellite Program Phases

The many spacecraft designed and constructed by Radio Amateurs since 1961 can be roughly classified by their intended function into three Phases. Phase I designs comprised the low Earth orbit (LEO), short lifetime, predominantly beacon-oriented satellites such as OSCARs I, II, III, and the Russian Iskra 1 and 2 series of spacecraft.

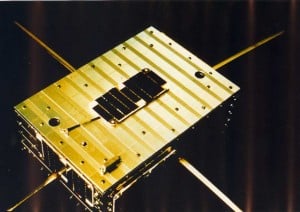

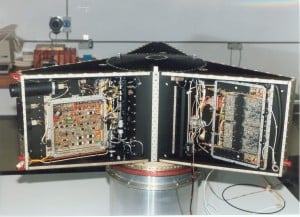

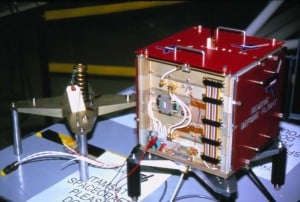

Phase II series OSCARs are also LEO “birds”, but are launched into somewhat higher orbits, and are designed for much longer lifetimes. These AMSAT satellites included OSCARs 6, 7, and 8, as well as UoSAT OSCARs 9 and 11, both of which were built by a team of AMSAT members and students at the University of Surrey in England. These satellites have since been followed by a series of both analog and digital-capable radio satellites which were launched by a variety of AMSAT groups from several countries into similar orbits. Back in the early 1990s, a number of these Amateur Radio satellites sported a design AMSAT’s experimenters pioneered called “MICROSATs’. This design consisted of small cubes, only 9 inches square and weighing in at about 20 pounds. They were designed to carry one or more store-and-forward digital transponders. This class of satellites has since given way to a whole new series of even smaller (and even less massive) satellites called “CubeSats”. This class of Amateur Radio satellites now make up the bulk of the nearly 20 Amateur radio satellites currently in orbit…with more to follow.

AMSAT’s Phase III satellites were each designed to be launched into a highly elliptical Molnya-type orbit first pioneered by the Soviet Union. These satellites included OSCARs 10, 13 and AO-40. These satellites offered their users much longer access time, higher power and more diverse communication transponders. What’s a more, these so-called “high altitude” satellite also offer their users far larger communications footprints than their LEO counterparts. That’s because Phase III satellites can “see” nearly an entire hemisphere of the Earth at the same time, allowing users the luxury of simultaneous contacts on one or more continents.

AMSAT-OSCAR Satellite Nomentclature

While worldwide AMSAT organizations are now largely responsible for the design and construction of the modern day Amateur Radio satellites, the term “OSCAR” is still being applied to most satellites carrying Amateur Radio. However, most Amateur Radio satellites are not usually assigned their sequential OSCAR numbers until after they successfully achieve orbit and become operational. Even then, an OSCAR number is only assigned after its sponsor formally requests one. If the satellite subsequently fails in orbit, or it re-enters the Earth’s atmosphere, its OSCAR number is usually retired, never to be issued again.

AMSAT MANAGEMENT APPROACH

Since its birth in 1969, AMSAT has grown into an international organization that has spun off a number of affiliate organizations in other countries. While the affiliations between the groups are not formal, they do often enter into one-time agreements to help each other with space-related projects.

That is, most of the subsequent work done on amateur satellites since OSCAR 5 has been by way of international efforts where teams of volunteers from one or more countries have helped build, launch, and/or control each other’s satellites. Usually, one or more national group(s) define the basic spacecraft and its interface requirements. Then, teams are formed from the various international pools to be responsible for the various systems and subsystems of the spacecraft.

This gives AMSAT’s design engineers substantial flexibility to create and manufacture innovative subsystem designs. Usually, any design is acceptable as long as it meets AMSAT’s basic operational criteria. This approach also allows each group to take maximum advantage of whatever materials and resources they already have on hand (or whatever they can find in the form of leftover materials or donations of materials from the aerospace industry!

AMSAT’s major source of operating revenue is obtained by offering yearly or lifetime memberships in the various international AMSAT organizations. Membership is open to Radio Amateurs and to others interested in the amateur exploration of space. Modest donations are also sought for tracking software and other satellite related publications at Amateur Radio gatherings. In addition, specific spacecraft development funds are established from time to time to receive both individual and corporate donations to help fund major AMSAT spacecraft projects.

However, in corporate terms, these funds usually yield operating capital that’s well below project budgets for comparable commercial satellite activities. For example, AMSAT-North America’s entire operating budget for 2014, including all the development funding generated from member donations toward AMSAT’s latest satellite project (the FOX Project) amounts to just a little more than $250,000.

From a personnel standpoint, AMSAT-North America is a true volunteer operation. The only person in the entire 3000-member organization drawing a regular paycheck is our office manager at our headquarters near Washington, DC. She conducts the day-to-day business of membership administration and other key organizational tasks. The rest of us, from the President of the Corporation, on down to the workers designing and building space hardware, all donate their time and talents to the organization.

While use of a decentralized, “all volunteer” army does have its drawbacks in managing a space program, the dividends are enormous in that it allows a single project to draw on the talents of many highly capable and well motivated people. Many of these volunteers are also aerospace professionals. To them, the aura of building, launching, controlling and then actually using the fruits of their labor once the satellite is in orbit is a powerful motivator for them to contribute their very best professional efforts.

Also, because vast sums of money are simply not available for development efforts, AMSAT’s management philosophy encourages innovation and simplicity by not “over specifying” the spacecraft’s design criteria. During development, subsystem designs are based predominantly on interface specifications with the rest of the spacecraft rather than by reams of detailed technical specifications at the subsystem level. The KISS approach…short for “Keep it Simple, Stupid”…is far more than just a buzzword for AMSAT’s design engineers. KISS, quite literally, permeates the entire management and design philosophy of AMSAT’s operations.

Oscar Satellite Construction Characteristics

As would be expected over nearly four decades of technological improvements, substantial advancements have been made in the features and capabilities of the OSCARs. However, the “home brew” flavor of these satellites lives on even in the most current AMSAT spacecraft designs.

For example, a substantial number of the subsystems for the 1980s-era OSCAR 13, one of AMSAT’s high altitude OSCARs, were concocted in home workshops. Several pieces of the spacecraft’s structure were purchased from an electronic surplus store in the Orlando, Florida area. In addition, all of AO-13’s fiberglass module’s mounting rails were cured in the kitchen stove of one of our AMSAT Vice Presidents! Material for spacecraft thermal blankets were also donated to the cause, and were subsequently hand sewn together by yet another AMSAT volunteer in their basement workshop.

Elements for AMSAT’s Phase 3-D spacecraft (that later became AO-40 on orbit) spacecraft structure were fabricated using similar “bargain basement” techniques. For example, although it was never deployed, AO-40’s 20 foot solar array was to have been stabilized in orbit using a device no more complex than an ordinary “bar door” hinge.

The spacecraft’s structure was made from ordinary sheet aluminum that was subsequently painted for thermal balance considerations. In addition, many of the spacecraft’s antennas consisted of ordinary flexible steel carpenter’s rule material and its kick motor and batteries consisted of leftover parts donated (or offered to AMSAT at substantially reduced cost) by aerospace corporations both in the USA and abroad.

Oscar Payloads, Capabilities, and Ground Station Requirements

Despite AMSAT’s “low tech” approach to satellite procurement and construction, the degree of technical sophistication of AMSAT’s satellites rivals that of many commercial satellites now flying. Over half of the 20 Amateur Radio satellites now in orbit carry what can best be described as “flying digital bulletin boards” Some of these satellites allow Radio Amateurs to connect and interact with them at speeds up to 9600 BPS using little more than laptop computers and “shoe box” sized radios.

The voice transponder capabilities of AMSAT satellites also offer users a variety of operating modes from Morse Code (CW) to Single Sideband (SSB) and Frequency Modulation (FM) voice. In addition, some OSCARs even allow their users to send and receive slow and fast scan television pictures to similarly equipped stations anywhere on the globe.

Ground station equipment to work these satellites is also easily obtainable and relatively inexpensive. For example, for about $3000 (much less if older or “home brew” gear is employed) any Ham can purchase enough commercial Amateur Radio equipment to assemble a ground station capable of interacting with any of the AMSAT satellites now in orbit. Whether for the digital or analog modes, this equipment can also usually be obtained off-the-shelf from any one of the hundreds of Amateur Radio dealers throughout the world.

ATTITUDE CONTROL AND STABILIZATION

As the missions of the OSCAR satellites have become more and more sophisticated, so, too, have the methods employed for OSCAR spacecraft attitude control and stabilization. However, they have not necessarily become more complex. Transponder antennas, even the fairly simple ones, have directivity characteristics. That’s why spacecraft attitude control is important to maintain useful communication links.

OSCAR spacecraft stabilization techniques run the gamut from simple bar magnets to computer controlled, active electromagnet systems for spin stabilization and attitude control. The latter type of system was used on all three of AMSAT’s Phase III spacecraft. It sensed both Earth and Sun positions, processed this data in an on-board computer, and then electronically controlled three sets of onboard electromagnets to achieve the proper spin rate and stabilization.

Other AMSAT spacecraft use gravity-gradient systems and magnetometry for attitude sensing. A rather elegant, yet simple design was employed by AMSAT’s MICROSAT series.

These small satellites used simple bar magnets mounted along the sides of the spacecraft to achieve “up and down” stability while in orbit. As with many other AMSAT spacecraft, antennas for the MICROSATs were made from ordinary flexible steel carpenter’s rule. However, while coating each antenna in the satellite’s turnstile array, AMSAT engineers alternated use of white and black paint so that, in space, these satellites would act just like those little radiometers we all played with as children! This design proved to be both highly reliable and very effective in keeping the MICROSATs properly oriented. It employed yet another KISS approach to spacecraft control by using the spacecraft’s onboard antennas to obtain spin stabilization energy directly from the Sun.

LAUNCH CONSIDERATIONS AND COSTS

While donated labor and salvaged materials help keep the cost of designing and building AMSAT satellites to a minimum, these are not the only areas of spacecraft operations that AMSAT has been able to achieve significant savings. In spite of all its other accomplishments, AMSAT does not have its own in-house launch capability! Most OSCAR satellites have been launched into orbit by riding as an extra passenger on a government or commercial agency’s booster.

However, AMSAT has taken this “piggyback” concept one step further. By employing a number of innovative design techniques that trade knowledge, skill and manufacturing capacity for a reduction (or outright waiver) of launch costs, AMSAT has also helped create additional launch capabilities for commercial launch providers in return for significantly lower cost access to space.

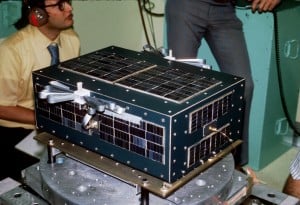

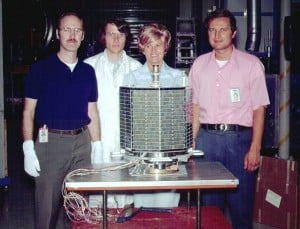

One of the most exciting examples of this concept was illustrated by the (Auxiliary Structure for Auxilliary Payloads) ASAP structure developed as a joint venture between the European Space Agency (ESA) and AMSAT. In the late 1980’s, AMSAT was in the process of building its MICROSAT series of small satellites. Obtaining a launch opportunity for not one, but six of these planned satellites posed a rather daunting challenge. However, AMSAT volunteer engineers approached the Eurpopean Space Agency (ESA) with an idea of how they might exploit some of the then unused space on their Ariane IV launch vehicle.

To make a long story short, in partnership with ESA, AMSAT helped design and manufacture a very large carrying structure (the ASAP) for use in launching small satellites. The structure fits around the base of the Ariane IV’s upper stage, and it served as the platform from which all six of AMSAT’s first MICROSATs were placed into orbit by ESA in 1990. In return, AMSAT obtained a significant reduction in launch costs. ESA has since used the ASAP structure to launch similar, albeit mostly commercial, satellites into orbit.

Thus, using a classic example of the “you scratch my back and I’ll scratch yours” approach, AMSAT obtained a virtually gratis launch opportunity while also advancing the state of the art in the space sciences. At the same time, AMSAT helped a commercial launch agency find a new way to improve the quality of its launch services and generate added revenue.

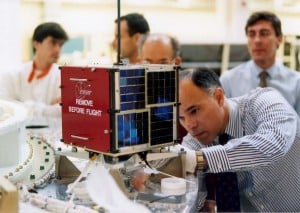

Another approach AMSAT uses for low cost access to space is to seek out test launches of new boosters or carrying structures. This technique has been employed with several OSCAR satellites, and was used again in conjunction with the development of another potentially attractive commercial carrying structure for the launch of AMSAT’s new Phase 3-D satellite.

AMSAT’s Phase 3-D satellite was launched into a geostationary transfer orbit (GTO) on an early launch of ESA’s new Ariane V heavy lift booster from Korou, French Guyana in 2000. It occupied what would otherwise have been unused space on the Ariane V’s upper stage by riding in an AMSAT designed cylinder underneath a “paying customer”. In return for this development effort, AMSAT received a significant reduction in the overall launch cost for Phase 3-D. While AMSAT assumed additional risks by riding on an early test of a new launch vehicle, the reduced costs associated with such a launch become were very attractive and quite difficult for an organization like AMSAT to turn down.

THE RISK OF FAILURE

While the loss of a satellite to a booster failure might be prohibitively expensive (in both monetary and political terms) to a commercial or military customer, AMSAT is in a much different position. If such a failure occurs, AMSAT simply loses the variable and direct costs of purchased materials and donations, and thousands of hours of concerted, yet still donated labor that’s been put into the spacecraft prior to its launch.

Sadly, this unfortunate turn of events has happened to AMSAT in the past when the first of the Phase III series, Phase 3-A, ended up in a “sub-Atlantic orbit” due to a disastrous failure of the spacecraft’s Ariane I booster during launch in May, 1980. Fortunately, Phase 3-A’s builders had the foresight to build the spacecraft with relatively “low tech” materials. That is, many of the materials used in Phase 3-A’s construction were readily available, or were already on hand when Phase 3-A was lost. Many had been used as test articles for the flight model spacecraft. Others could be obtained simply by making another trip to the surplus store! So, with a whole lot of additional volunteer effort, AMSAT Phase 3-B was successfully launched in June of 1983, and became AMSAT-OSCAR 10 upon reaching orbit.

Then, as noted earlier, in 2000, AMSAT’s international Phase 3-D satellite (which later became AO-40 on orbit) met with near-disaster when its kick-motor (a bi-propellant device that was designed to boost the satellite into its final Molnya orbit) malfunctioned on orbit and caused what AMSAT experimenters believe was a near-fatal explosion. After several frantic weeks, the satellite was eventually recovered and went on to provide many years of useful service.

Because it is usually prohibitively expensive, launch insurance is seldom, if ever, purchased for AMSAT satellites. Rather, to minimize risk, AMSAT makes a concerted attempt to obtain or manufacture duplicate copies of structural or other components whenever possible, or to launch multiple satellites or duplicate transponders with the same or similar characteristics. This can be somewhat difficult to accomplish when donated items turn out to be “the last one we have” or are “one of a kind”. For each satellite it proposes to launch, AMSAT usually builds at least two space frames. In many cases, engineering test items also serve as backups to actual flight hardware.

CLEANLINESS, QUALITY CONTROL AND RELIABILITY

Because AMSAT is operating at the “bargain basement” cost threshold, one would also think that skimping on quality control issues, operational testing, or standards of cleanliness would be a way of life. Such is not the case. AMSAT’s volunteer engineers make every attempt to insure AMSAT spacecraft are designed for safe, contaminant free and reliable operation. However, AMSAT uses methods to achieve these goals that center on common sense and a “no-more-than-is-actually-needed” approach.

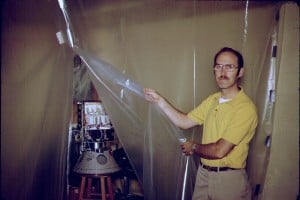

For example, clean room facilities used in the assembly of most AMSAT satellites are not at all sophisticated, but yet AMSAT’s track record for cleanliness rivals that of any commercial spacecraft manufacturer. While a commercial clean room facility may consist of a special multi-million dollar, air conditioned complex, an AMSAT clean room assembly facility may simply be constructed from sheet plastic and 2×4 stud-quality lumber nailed together in someone’s basement.

Where a commercial facility may have all the latest cleaning machinery, the equivalent AMSAT facility may employ cleaning equipment that’s no more sophisticated than an ordinary household vacuum cleaner. It is interesting to note, however, that despite AMSAT’s unsophisticated approach to cleanliness, not a single AMSAT satellite presented to a launch agency for subsequent launch has ever been rejected for lack of cleanliness or contaminated parts!

Each AMSAT spacecraft is subjected to most of the same tough environmental and thermal tests as their commercial and military counterparts to assure they are not a hazard to the launch mission. In addition, AMSAT engineers exercise great care in the selection and assembly of materials to insure they will not contaminate the spacecraft’s environment or fail soon after launch. Environmental testing (so-called “Shake and Bake”) time in commercial or governmental test facilities is often donated to AMSAT during “off peak” periods for this testing.

Also, where Mil-Specs or NASA Standards for components and procedures make sense, they are employed in the spacecraft’s design and

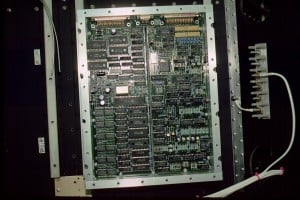

construction. If commercial quality (or surplus store quality!) will suffice, it, too, is employed. As a result, value considerations play a predominant role in AMSAT’s spacecraft construction, and “gold plating”, where determined necessary, is kept to an absolute minimum. Back-up systems and redundancy are frequently designed into the spacecraft, with emphasis on employing safe, reliable and proven designs, even if these designs would be considered “ancient” in the commercial world.

For example, the onboard Internal Housekeeping Unit (IHU) computer for AMSAT’s AO-40 satellite employed a simple computer design built around a single, radiation hardened “1802” microprocessor chip. This is the same design that was successfully previously used onboard both OSCARs 10 and 13. This single chip processor, with only 16K of memory was considered archaic by the computer processor standards even back in the early 1990s. However, as the IHU’s tasks onboard many of AMSAT’s satellites are relatively routine, they often do not require anything more sophisticated than a small amount of processing power to perform. What’s more, much of the software code for many of AMSAT’s satellites had already been written and extensively “de-bugged” for a number of previous satellite designs. In many cases, IHU hardware and software had already proven themselves to be “fail safe” and extremely reliable, even after running onboard similar satellites for many years. Put another way, AMSAT’s IHU design wasn’t broken, and AMSAT’s engineers were not about to “fix” it!

DOCUMENTATION

Documentation and configuration control standards for AMSAT spacecraft take on a similar flavor. Common sense is the rule rather than the exception. For example, the entire spacecraft drawings and system descriptions for one of AMSAT’s most sophisticated spacecraft design during the 1980s consisted of a single 234-page book. Simply called the “Red Book” by AMSAT engineers, it contained information that described the AO-13 satellite in enough detail so that a similar satellite could be built using the same drawings. In fact, such a feat was successfully accomplished when Phase 3-A was lost. AMSAT engineers used a similar book to design and construct Phase 3-B, which later became OSCAR 10 in 1983.

With the advent of more sophisticated design tools, AMSAT started using CAD techniques to design the Phase 3-D (later AO-40) satellite. However, even here, simplicity was rule. Before launch, Phase 3-D was conservatively estimated to have a commercial value exceeding $80 Million, yet the entire spacecraft’s design (including its carrying structure for the Ariane V) was reflected in only 75 CAD drawings. What’s more, strict change order control procedures were put in place to document and monitor changes to the design. However, these were “common sense” rules that are simple to implement and serve no other purpose than to protect the integrity of the Phase 3-D design for possible replication in the future.

EDUCATIONAL EFFORTS

In addition to its unmanned satellite efforts, AMSAT has also been active in several educational activities. One that has been particularly productive is our University Partnership Program. In this program, AMSAT establishes mutually productive working agreements with one or more universities around the world to help with satellite construction or other work in support of AMSAT’s many projects.

For instance, the Phase 3-D spacecraft structure (along with its carrying structure) were built by a team of students at the Center for Aerospace Technology at Weber State University in Ogden, Utah.

AMSAT’s partnership with Weber was nothing short of a “win-win” situation for both parties. That is, Weber students got an invaluable, “hands on” educational experience building real flight hardware. In return, AMSAT got access to some very high quality student labor at a substantially reduced cost. Over the years, AMSAT has achieved great benefit from these arrangements, as the quality of student workmanship has usually far exceeded AMSAT’s specifications.

In another educational pursuit, AMSAT joined with the American Radio Relay League (ARRL) and the National Aeronautics and Space Administration (NASA), to developed new space-qualified Amateur Radio hardware for NASA’s Space Shuttle, and later, for the International Space Station (ISS). What’s more, AMSAT volunteers regularly donate their technical communications “know-how” to each flight involving Amateur Radio operations aboard the Shuttle. In recent years this program, called ARISS (which is short for Amateur Radio on the International Space Station), has been used to bring school children in a number of countries into direct radio contact with the orbiting Shuttle astronauts.

CONCLUSIONS

The story of AMSAT is one of simplicity, selfless donation of time and resources, and a pioneering spirit. The Amateur Radio Operators of Project OSCAR, and their later counterparts in AMSAT and other organizations, have built and launched over 60 OSCAR satellites since 1961. Their efforts are largely responsible for many of the commercial satellite technologies we take for granted today.

Real-time satellite communications technologies ranging from voice transponders to digital store-and-forward techniques to multiple satellite launch adapters that allow simultaneous launch of small satellites were all outgrowths of the vision of AMSAT members and the actual fabrication of space-qualified materials by many of them in their basement workshops.

What’s more, AMSAT was pioneering small satellite technology when “big” satellites were being touted in the commercial and government sector as “the only way to go”. Indeed, a number of billion dollar commercial ventures have launched constellations of hundreds of similar small satellites for digital store-and-forward messaging. These satellites exploit many of the technical breakthroughs that were first pioneered by AMSAT.

AMSAT’s management approach is designed to optimize technical excellence in a “not-for-profit”, “all-volunteer” environment. However, commercial and governmental agencies can still draw some valuable lessons from AMSAT’s KISS approach. The results are simple, yet highly reliable, innovative and cost-effective designs for spacecraft hardware and software. Indeed, the lack of vast amounts of available working capital forces AMSAT designers to seek out the most cost- effective satellite hardware and software designs. In addition, the continued use of proven technologies for similar applications, even where those technologies might be viewed in the commercial world as “ancient”, also keeps costs low. Finally, the creative use of redundancy and cooperative effort between AMSAT, universities, and launch agencies helps each activity keep their respective services cost-effective. Hardware and software documentation is kept to an absolute minimum. What is published is accomplished in only enough detail so that hardware or software items can be duplicated in the future if need be.

Many people may scoff at a bunch of “amateurs” who work in their basements and garages to build space satellites. However, the past and present volunteers of AMSAT are “amateurs” only in the sense that the Wright Brothers, Marconi or Robert Goddard were “amateurs”. The latter were pioneers who used available materials and creativity to design, build and operate devices whose modern day counterparts we now take for granted. That same pioneering spirit has been a hallmark of AMSAT’s technical and managerial approach since its founding in 1969.

For the past 40 years international AMSAT groups have played a key role in significantly advancing the state of the art in the space sciences, space education and space communications technology. Undoubtedly, the work now being done by AMSAT’s volunteers throughout the world will continue to have far reaching, positive effects on the very future of Amateur Radio communication, as well as other governmental, scientific and commercial activities in the final frontier.

The nearly 20 operational OSCAR satellites now orbiting the Earth are a living testament to the spirit and vision of AMSAT’s membership. Rarely has a group of volunteers managed to do so much …for so many…with so little.

SELECTED REFERENCES

Baker, Keith, and Jansson, Richard, Space Satellites from The World’s Garage, The Story of AMSAT: Proceedings of National Aerospace and Electronics Conference (NAECON), 1994

Davidoff, Martin, The Satellite Experimenter’s Handbook, Newington, CT: The American Radio Relay League, 1984.

Jansson, Richard, Spacecraft Technology Trends in the Amateur Satellite Service, Ogden, UT: Proceedings of the 1st Annual USU Conference on Small Satellites, 1987.